Online

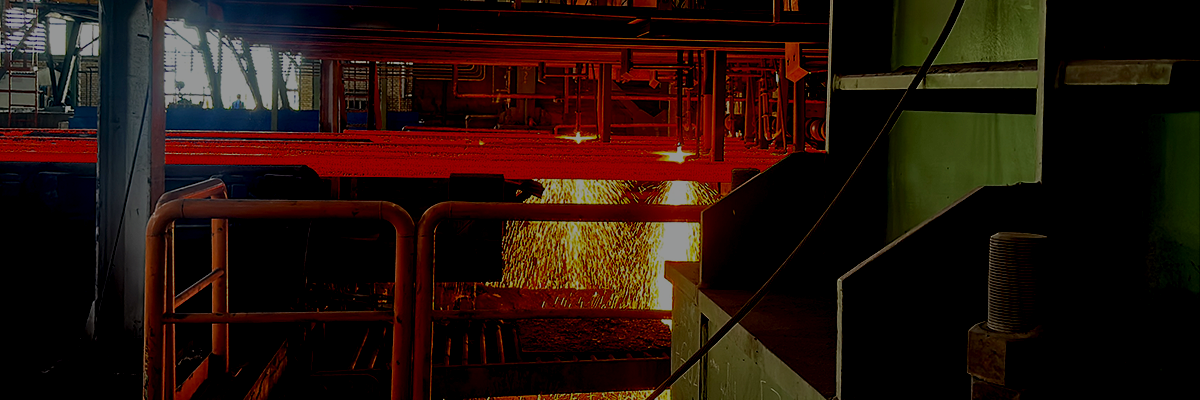

Graphite electrode is one of the important raw materials of steel industry. EAF&LF uses graphite electrode to introduce current into the furnace, and uses the high temperature heat source generated by the arc between the electrode end and the charge to smelt.

Graphite electrode is used in submerged arc furnaces. The lower part of the conductive electrode is buried in the charge, an arc is formed in the charge layer, and the heat energy generated by the resistance of the charge itself is used to heat the charge to produce industrial silicon and yellow phosphorus.

Semiconductors are indispensable in our lives. Computers, solar cells, and LEDs all work with semiconductors. High-purity graphite is an indispensable product in the semiconductor manufacturing process. Yetan Shanghai Graphite Co., Ltd. can manufacture components according to customer needs and assist you in planning, designing, and optimizing operations. We have a wealth of products in processing high-purity products that can meet your requirements and are worthy of your trust.

The particle size of medium-coarse graphite is mainly 0.2/0.4/0.8/2MM. It can be processed into graphite materials for graphitization furnaces, carbon materials; various graphite tube series; graphite plate series; graphite crucible series; 25/50mm light rods; various carbon blocks, furnace bottom blocks; 100, 150, 200 diameter graphite rods, graphite electrodes. At the same time, it can also follow up customer requirements and process into different types of graphite parts and fasteners, spring rings, spring washers and graphite brake discs.

With the accelerated development of new energy, new energy storage is highly expected as a solution to improve the safe and efficient utilization rate of new energy. We will continue to improve the new energy storage policy system, continue to promote the progress of new energy storage technology industry, scientifically configure and dispatch various types of energy storage, and support the construction of new energy systems and new power systems. We can provide customers with land transport standard prefabricated cabins, container prefabricated cabins, photovoltaic inverter containers, photovoltaic energy storage power station prefabricated cabins, SVG prefabricated cabins, LNG mobile gas stations, container mobile villas and other energy storage equipment.

In our daily life and industrial production, there is a class of seemingly inconspicuous small objects that play a vital role - they are fasteners. Bolts, nuts, screws, washers and other types of fasteners, although small in size, are indispensable connectors in various mechanical equipment, building structures and household items. The application of fasteners covers almost all industrial fields and daily life. In the future, with the advancement of science and technology and the improvement of people's requirements for quality and environmental protection, the fastener industry will usher in more development opportunities and challenges.

During the smelting process, due to improper batching or charging and excessive decarburization, the carbon content in steel or iron sometimes does not meet the expected requirements. At this time, carbon should be added to the steel or molten iron. According to different smelting methods, furnace types and smelting furnace sizes, it is also important to choose the appropriate carburizer particle size, which can effectively increase the absorption speed and absorption rate of the molten iron to the carburizer and avoid the oxidation and burning of the carburizer caused by too small particle size. The higher the fixed carbon content, the better, and the lower the content of harmful impurities such as ash, volatile matter and sulfur, the better, so as not to contaminate the steel. Carburizer can also be used in the petrochemical industry and plays a lubricating role in the oil drilling industry.

As a key national support area, new energy electric vehicles will surely see a blowout development from 2015 to 2025. Graphite negative electrode materials for lithium-ion batteries are one of the main components of lithium batteries, and all graphite negative electrode materials need to be purified by high-temperature graphitization in graphite crucibles to achieve a layered structure with low ash, high purity and high graphitization degree.

Our graphite crucibles include straight-cylinder artificial crucibles and new plum-shaped artificial crucibles. The resistor materials of the two crucibles are loaded into the graphitization furnace, and the temperature reaches 2800℃ after power transmission and heating, thereby achieving the heat treatment effect.

The new plum-shaped crucible container allows the current to pass through the crucible body evenly to generate heat. The crucible is both a loading container and a heating element, which greatly reduces the power consumption of high-temperature purification, shortens the power transmission time, and achieves the purpose of uniform heating of the processed materials and improving the heat utilization efficiency. It can effectively improve the initial charge and discharge capacity and compaction density of the negative electrode material, reduce the specific surface area and rebound coefficient, and ultimately achieve the dual benefits of improving product quality and reducing costs.

Contact Us